ENGINEERING SERVICES

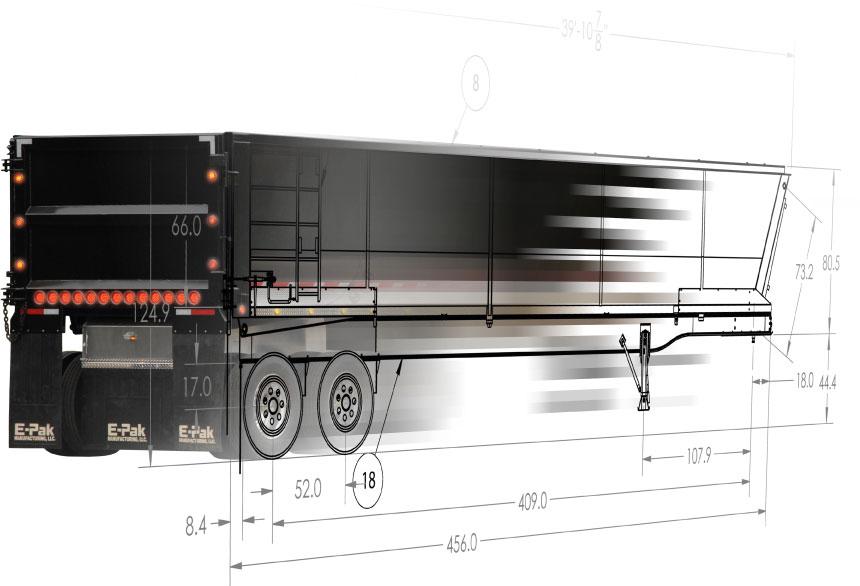

The containers, boxes, and trailers manufactured by E-Pak are known for their durability and sturdiness. Our products stand the test of time because of the attention to detail and precision engineering that goes into everything we make. Here’s a look at some of the equipment and our capacities that make custom design to your exact specifications possible.

FINDING SOLUTIONS

We continue to expand our product offerings each year to meet the needs of new and existing customers. Some of those more recent additions include updated environmental containers and new trailer designs.

Can’t find what you are looking for? Contact us below and together we will find a solution.